Minimize pollutants and the emission of volatile organic compounds when pressurizing the refrigerant gas mix

Compression Train Solutions

Centrifugal compressors are the main components of the gas liquefaction train. They are typically a multi-stage compression of refrigerants necessary to ensure that natural gas reaches its liquid state for storage and transport. The entire refrigeration cycle relies on robust compressors to ensure uninterrupted LNG production.

What's your opportunity?

- Achieve maximum compressor efficiency and high throughput

- Protect critical compressor from surges, failures, and shutdowns

- Avoid pollutants and dangerous emissions of volatile organic compounds

Featured Compression Train Solutionss

Protect your critical and costly compressor from a damaging surge event with a complete optimized anti-surge valve package that provides higher gains, precise response, and remarkable stability.

- The Fisher control valve provides quick, accurate response during a surge to recycle the discharge flow back to the suction side of the compressor, avoiding expensive and disruptive damage

- The Fisher SS-263 volume boosters offer three times the capacity of traditional boosters, high vibration resistance, enhanced throttling control, and a desirable fail-safe mode

- The FIELDVUE ODV-tier digital valve controller is dual certified as intrinsically safe and explosion proof, and offers an anti-surge-specific tuning capability

Website: Fisher Anti-Surge Valve Solutions

Maintain the appropriate temperature of the oil lubricant.

- Throttling or flow switching service

- Cavity-free

- Non-rubbing design completely eliminates wear on sealing surfaces

.

Website: Fisher YD and YS

Shut off the flow of a hazardous gas upon detection of a dangerous event.

- Torque assisted elastic metal seal ensures continuous bi-directional, zero leakage performance

Website: Fisher Digital Isolation TOV product

Recycle gas around the entire set of compressors as a safety feature so they won’t shut down.

- Very large size of up to NPS 36 to accommodate the capacity rates of the compressors

- Quick opening time

Website: Fisher EW product

Ensure consistently tight shutoff despite temperature and pressure changes.

- Torque seated, zero leakage shutoff

- Trapped cavity risk eliminated

- Zero maintenance with non-rubbing design

Websites:

Provide True-Modulating overpressure protection at the compressor outlets with a product designed to minimize nuisance reliefs.

- Robust bracketing and tubing minimize the impact of vibration of the pressure relief valve

- Spike snubbers smooth pressure waves at the valve inlet reducing accidental reliefs

Website: Anderson Greenwood Series 400

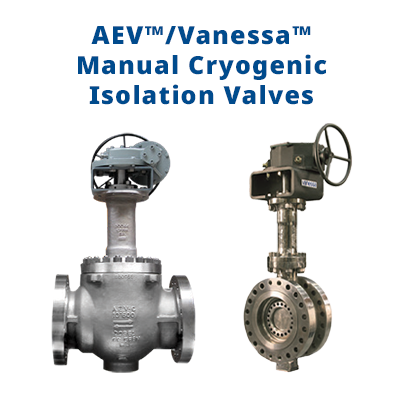

Isolate your critical liquefaction facility assets with confidence for inspection and repair events.

Brochure: Isolation Valve Product