Produce more LNG with high precision controlling elements that enable optimal controller tuning

Main Cryogenic Heat Exchanger Solutions

The main cryogenic heat exchanger (MCHE) is the heart of the liquefaction facility. It liquefies natural gas then subcools it. The MCHE is composed of a large number of spiral wound tube bundles. When the feed gas exits the top of the MCHE, it has been turned into liquid as the temperature has been reduced to approximately -146°C (-231°F).

What's your opportunity?

- Maintain optimum refrigerant flow circulation

- Reduce energy consumption when feed is restricted

Featured Main Cryogenic Heat Exchanger Solutions

Utilize pressure drop to achieve cooling of liquids, gases or multi-phase fluids.

- Withstands full cryogenic temperatures

- Maintains stable flow of refrigerant to chillers and cold boxes under large differential pressures

- High precision assembly with ≤ .25% deadband

Control of the temperature of LNG coming out of the main heat exchanger.

- Drilled hole trim in flow up direction so flashing and/or outgassing is directed away from trim

- Expanded outlet valve body design allows for downstream expansion of lighter hydrocarbon constituents

Ensure consistently tight shutoff despite temperature and pressure changes.

- Torque seated, zero leakage shutoff

- Trapped cavity risk eliminated

- Zero maintenance with non-rubbing design

Websites:

Inject LNG into the gas to cool it.

- Wide range of KV capacities

- Multiple atomizer technology

- Near uniform spray quality over the entire operating range

Shut off the flow of a hazardous gas upon detection of a dangerous event.

- Torque assisted elastic metal seal ensures continuous bi-directional, zero leakage performance

- Cryogenic extension

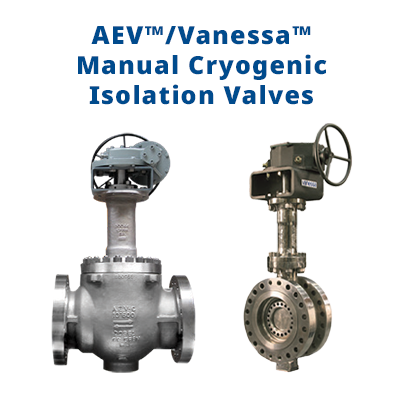

Isolate your critical liquefaction facility assets with confidence for inspection and repair events.

- Torque assisted elastic metal seal continuous bi-directional, zero leakage performance

Ensure overpressure protection at the slug catcher without leakage or excess fluid loss.

- Modulation action minimizes fluid lost during relief events

- Bubble tight seating during normal operation

- Large full bore orifices available for large capacity requirements

Double acting and spring return pneumatic quarter turn actuators for on-off and modulating control of valves in heavy duty service and for high pressure supply (OLGA-H/OLGAS-H). Available for output torques to 750,000 Nm.

Valve function - Ensure consistently tight shutoff despite temperature and pressure changes.

Websites:

Low pressure, double acting and spring return pneumatic linear valve actuators for on-off and regulating service.

Valve function - Control the temperature of LNG coming out of the main heat exchanger.

Type EHO double-acting and spring-return SMART self-contained Electro-Hydraulic quarter-turn actuators for critical shutdown applications where reliability is crucial.

Type EFS 2000 v4 series are electric quarter turn spring return actuators for closing and opening a valve in emergency conditions.

Valve function - Ensure consistently tight shutoff despite temperature and pressure changes.

Double acting and spring return pneumatic quarter turn actuators for on-off and modulating control of valves in heavy duty service and for high pressure supply (OLGA-H/OLGAS-H). Available for output torques to 750,000 Nm.

Valve function - Shut off the flow of a hazardous gas upon detection of a dangerous event.

Websites:

Low pressure, double acting and spring return pneumatic linear valve actuators for on-off and regulating service.

Valve function - Utilize pressure drop to achieve cooling of liquids, gases, or multi- phase fluids.

Website: Biffi PLA - PLAS